Axial Tube Fans

Falvent is a leading manufacture of ventilation solutions for industrial and commercial applications. With a focus on innovation and customer satisfaction, we offer a range of products designed to meet the unique needs of our clients. Our team of experts is dedicated to delivering high-quality products and exceptional service.

Falvent assemble and design the finest axial fans on the market with competitive prices and our team works hard to ensure that you receive the highest quality custom-designed axial fans, precisely as ordered and delivered on time to meet your project goals.

The range of axial fan sizes and capacities cover low to medium pressure systems for ventilation as well as for removal and transport of air within practically all environments. Falvent axial fans obtained the UL Certification which guarantees the compliance of the products with the safety requirements. Falvent axial fans tested in accordance with UL-705 standard and certified in ZACT: Power Ventilators category and rigorous tests have been carried out via UL team like temperature test, water spray test, dielectric voltage test and starting current test. Thus, Falvent axial fans have product safety certification UL logo.

Falvent has met the requirements in ISO 9001, which defines an ISO 9001 Quality Management System (QMS) and obtained the ISO certification accordingly. Falvent axial fans has CE mark logo where it declared with EEE regulations and meets the requirements of the relevant European product safety legislation.

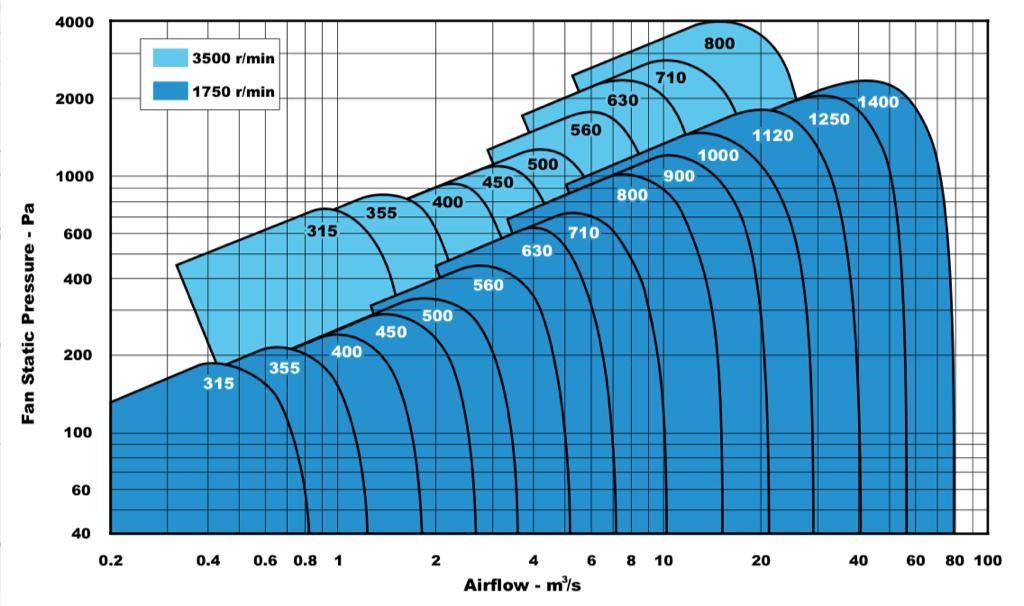

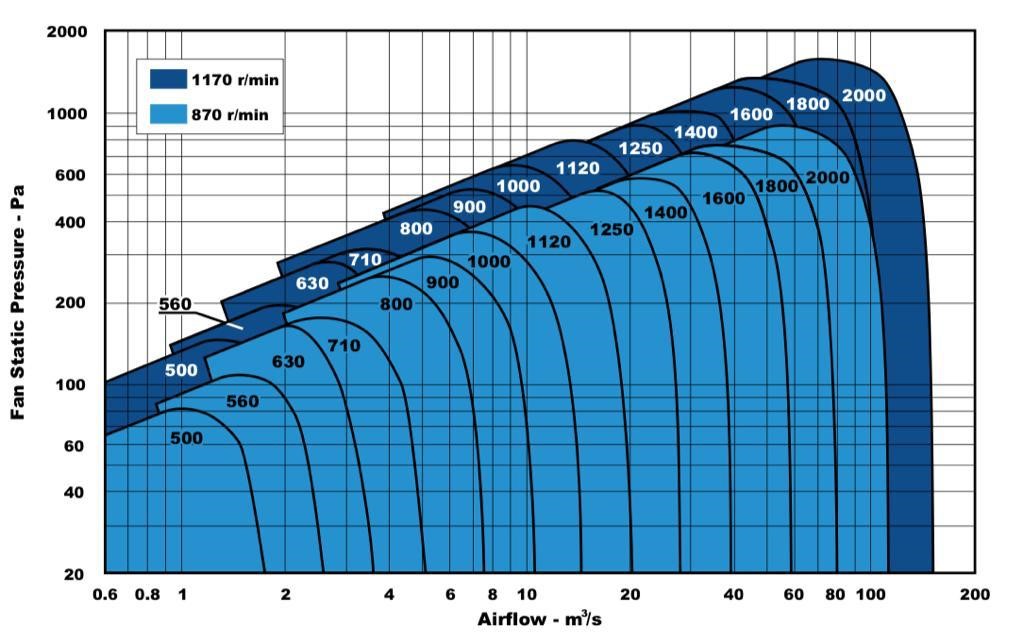

The fan casings are constructed from a heavy gauge sheet steel, rolled, spun flanged and fully welded, then epoxy coated after fabrication. Motor bases is placed inside the casings and constructed from a heavy gauge sheet steel. Both motors and axial impellers are mounted within the length of the casing. Sizes: 315, 355, 400, 450, 500, 560, 630, 710, 800, 900,1000, 1120, 1250, 1400 & 1600 mm.

Two stage fans (two fans in series) are available for high static pressure. Pre-wired terminal block (rail mounted type) is fitted inside junction box (screw type) located on the outside of the fan casing for easy wiring access and protects all wiring connections against the ingress of dust and moisture. Wire pulls through liquid tight flexible conduit and connect with the junction box via connector. Terminal block, junction box, liquid tight flexible conduit and wire are UL certified.

Impellers are manufactured from die-cast aluminum alloy, dynamically balanced according to ISO 1940-1 to minimize vibration levels and assure smooth operation.

Impeller blades are mounted into a hub and clamp plate assembly, which allows manual blade pitch angle adjustment that achieve the optimum selection.

The standard range comprises 15 sizes with impeller diameters from 315 to 1600 mm and 6 hub diameters from 280 to 550 mm Optimized design through CFD simulation and actual testing.

All motors three Phase asynchronous motor, WEG brand, UL certified, IEC standard motors in IE3, with lower acquisition cost and high technology, easy installation, easy operation and low maintenance cost and suitable for the use with Frequency Inverters. Motors are foot mounted, totally enclosed type to IP55 with a standard industrial paint finish and Class F insulation, TEFC cooling method and wired via a weatherproofed cable.

Motors are provided with Thermistor (PTC) with the resistance increasing drastically to a welldefined temperature figure. This sudden resistance variation blocks the PTC current, causing the output relay to operate, and the main circuit to switch-off. Motors are fitted with highest quality bearing selected and designed to ensure the long life time of the motors.

Electrical supply: 380-400V/60Hz/3Ph.

- AXF Fan

- Vibration Isolator

- Mounting Feet

- Wire Guard

- Flexible Connector

- Matching Flange

- Back Draft Shutter

- Sound Attenuator

PRODUCT CODE

(AXF: 630 D4 2.2)- AXF: denotes fan type

- 630: denotes impeller diameter in millimeters

- D: denotes 3 ph motor.

- 4: denotes a nominal 4 pole speed

- 2.2: denotes the motor power in kw.

| Model | Impeller Dia | Max Air Flow | P.out | Full Load Ampere | Voltag | Frequency | Phase | Speed | Noise Level | |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | hr/m3 | s/m3 | (Kw) | (A) | (V) | (Hz) | rpm | db | ||

| AXF 315 D2 0.55 | 315 | 3250 | 0.9 | 0.55 | 1.26 | 380 | 60 | 3 | 3450 | 346805 |

| AXF 315 D4 0.25 | 315 | 1550 | 0.43 | 0.25 | 0.739 | 380 | 60 | 3 | 1740 | 346806 |

| AXF 315 D4 0.37 | 315 | 1760 | 0.49 | 0.37 | 0.96 | 380 | 60 | 3 | 1740 | 346807 |

| AXF 355 D2 1.1 | 355 | 5880 | 1.63 | 1.1 | 2.33 | 380 | 60 | 3 | 3450 | 346808 |

| AXF 355 D4 0.55 | 355 | 3100 | 0.86 | 0.55 | 1.23 | 380 | 60 | 3 | 1740 | 346809 |

| AXF 400 D2 1.5 | 400 | 8600 | 2.39 | 1.5 | 3.09 | 380 | 60 | 3 | 3450 | 346810 |

| AXF 400 D4 0.75 | 400 | 5150 | 1.43 | 0.75 | 1.71 | 380 | 60 | 3 | 1740 | 346811 |

| AXF 450 D2 2.2 | 450 | 12750 | 3.54 | 2.2 | 4.45 | 380 | 60 | 3 | 3450 | 346812 |

| AXF 450 D4 0.55 | 450 | 7100 | 1.97 | 0.55 | 1.23 | 380 | 60 | 3 | 1740 | 346813 |

| AXF 500 D2 4.0 | 500 | 19630 | 5.45 | 4 | 7.6 | 380 | 60 | 3 | 3450 | 346814 |

| AXF 500 D4 0.75 | 500 | 10400 | 2.89 | 0.75 | 1.68 | 380 | 60 | 3 | 1740 | 346815 |

| AXF 560 D2 4.0 | 560 | 23400 | 6.5 | 4 | 7.6 | 380 | 60 | 3 | 3450 | 346816 |

| AXF 560 D4 1.5 | 560 | 15300 | 4.25 | 1.5 | 3.15 | 380 | 60 | 3 | 1740 | 346817 |

| AXF 630 D4 2.2 | 630 | 22100 | 6.14 | 2.2 | 4.72 | 380 | 60 | 3 | 1740 | 346818 |

| AXF 630 D4 3.0 | 630 | 25400 | 7.06 | 3 | 6.98 | 380 | 60 | 3 | 1740 | 346819 |

| AXF 630 D4 4.0 | 630 | 29250 | 8.13 | 4 | 8.03 | 380 | 60 | 3 | 1740 | 346820 |

| AXF 710 D4 3.0 | 710 | 29400 | 8.17 | 3 | 6.98 | 380 | 60 | 3 | 1740 | 346821 |

| AXF 710 D4 4.0 | 710 | 32600 | 9.06 | 4 | 8.03 | 380 | 60 | 3 | 1740 | 346822 |

| AXF 710 D4 5.5 | 710 | 35100 | 9.75 | 5.5 | 10.4 | 380 | 60 | 3 | 1740 | 346823 |

| AXF 710 D4 7.5 | 710 | 39150 | 10.88 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346824 |

| AXF 800 D4 5.5 | 800 | 37450 | 10.4 | 5.5 | 10.4 | 380 | 60 | 3 | 1740 | 346825 |

| AXF 800 D4 7.5 | 800 | 42550 | 11.82 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346826 |

| AXF 900 D4 7.5 | 900 | 53000 | 14.72 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346827 |

| AXF 900 D6 4.0 | 900 | 41500 | 11.53 | 4 | 8.99 | 380 | 60 | 3 | 1150 | 346828 |

| AXF 1000 D4 15.0 | 1000 | 71850 | 19.96 | 15 | 28.7 | 380 | 60 | 3 | 1740 | 346829 |

| AXF 1000 D4 18.5 | 1000 | 77100 | 21.42 | 18.5 | 33.9 | 380 | 60 | 3 | 1740 | 346830 |

| AXF 1000 D6 5.5 | 1000 | 62270 | 17.3 | 5.5 | 12.5 | 380 | 60 | 3 | 1150 | 346831 |

| AXF 1120 D4 18.5 | 1120 | 79800 | 22.17 | 18.5 | 33.9 | 380 | 60 | 3 | 1740 | 346832 |

| AXF 1120 D6 7.5 | 1120 | 64900 | 18.03 | 7.5 | 15.9 | 380 | 60 | 3 | 1150 | 346833 |

| AXF 1120 D6 11.0 | 1120 | 72400 | 20.11 | 11 | 22 | 380 | 60 | 3 | 1740 | 346834 |

| AXF 1250 D4 37.0 | 1250 | 110650 | 30.74 | 37 | 66.1 | 380 | 60 | 3 | 1740 | 346835 |

| AXF 1250 D6 15.0 | 1250 | 92400 | 25.67 | 15 | 28.3 | 380 | 60 | 3 | 1150 | 346836 |

| AXF 1400 D6 30.0 | 1400 | 142500 | 39.58 | 30 | 58.8 | 380 | 60 | 3 | 1150 | 346837 |

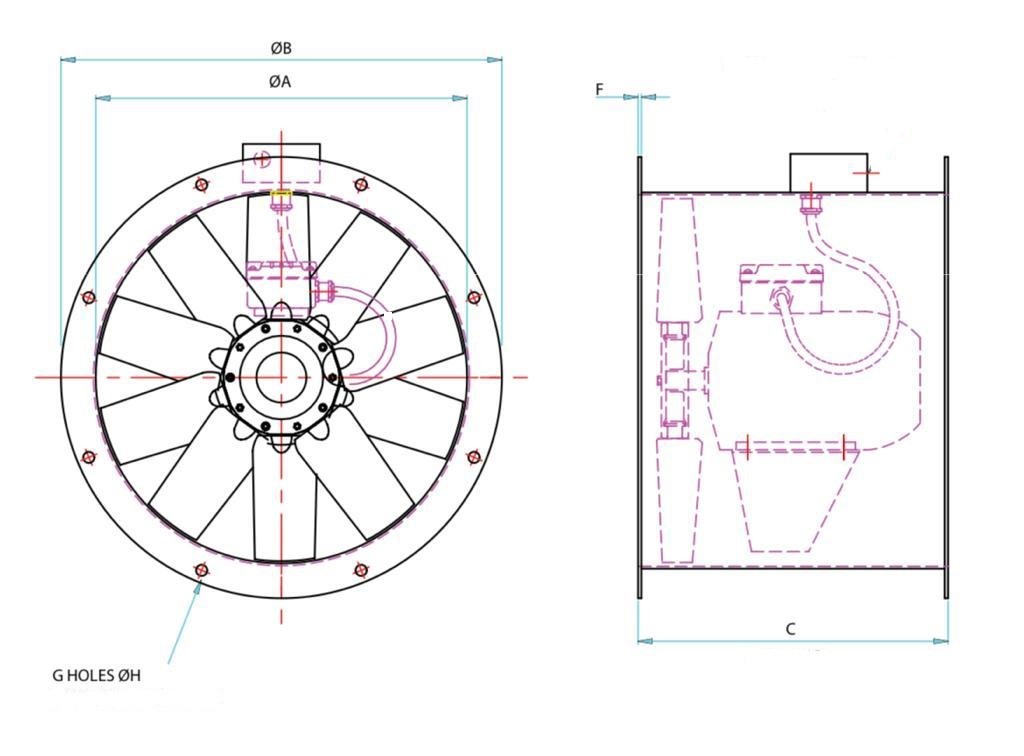

THE DIMENSIONS OF THE LONG CASE AXIAL FANS DEPEND ON SEVERAL FACTORS AS FOLLOWS:

- Impeller diameter.

- Hub diameter.

- Motor size and dimensions.

- Base of Motor (B3 or B5)

| Model | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| 315-63/71 | 300 | 180 | 295 | 2 | 8 | 10 | 355 | 21 | ||

| 315 | 375 | |||||||||

| 315-80 | 400 | 220 | 324 | 2 | 21 | |||||

| 355-63/71 | 300 | 220 | 295 | 3 | 8 | 10 | 395 | 21 | ||

| 355 | 425 | 21 | ||||||||

| 355-80/90 | 400 | 220 | 375 | 3 | 21 | |||||

| 400-63/71/80/90 | 400 | 475 | 400 | 220 | 375 | 3 | 8 | 12 | 450 | 21 |

| 450-63/71/80/90 | 400 | 220 | 375 | 3 | 8 | 12 | 500 | 21 | ||

| 450 | 530 | |||||||||

| 450-100/112 | 450 | 250 | 335 | 3 | 21/26 | |||||

| 500-63/71/80/90 | 400 | 220 | 375 | 3 | 12 | 12 | 560 | 21 | ||

| 500 | 585 | |||||||||

| 500-100/112 | 450 | 250 | 435 | 3 | 21/26 | |||||

| 560-71/80/90 | 400 | 220 | 375 | 3 | 12 | 12 | 620 | 21 | ||

| 560-100/112 | 560 | 645 | 450 | 250 | 435 | 3 | 21/26 | |||

| 560-132 | 570 | 300 | 555 | 3 | 26 | |||||

| 630-71/80/90 | 400 | 250 | 375 | 3 | 12 | 12 | 690 | 21 | ||

| 630-100/112 | 450 | 250 | 435 | 3 | 21/26 | |||||

| 630 | 715 | |||||||||

| 630-132 | 570 | 300 | 555 | 3 | 26 | |||||

| 630-160 | 710 | 400 | 685 | 4 | 33 | |||||

| 710-80/90/100/112 | 450 | 250 | 435 | 3 | 16 | 12 | 770 | 21/26 | ||

| 710-132 | 570 | 300 | 555 | 3 | 26 | |||||

| 710-160 | 710 | 795 | 710 | 400 | 685 | 4 | 33 | |||

| 710-180 | 790 | 500 | 760 | 4 | 42 | |||||

| 710-200 | 840 | 550 | 822 | 5 | 53 | |||||

| 800-80/90/100/112 | 450 | 250 | 435 | 3 | 16 | 12 | 860 | 21/26 | ||

| 800-132 | 570 | 300 | 555 | 3 | 26 | |||||

| 800-160 | 800 | 885 | 710 | 400 | 685 | 4 | 33 | |||

| 800-180 | 790 | 500 | 760 | 4 | 42 | |||||

| 800-200 | 840 | 550 | 822 | 5 | 53 | |||||

| 900-80/90/100/112 | 450 | 250 | 435 | 4 | 16 | 15 | 970 | 21/26 | ||

| 900-132 | 570 | 300 | 555 | 4 | 26 | |||||

| 900 | 1000 | |||||||||

| 900-160 | 710 | 420 | 685 | 4 | 33 | |||||

| 900-180 | 790 | 500 | 760 | 4 | 42 | |||||

| 1000-80/90/100 | 450 | 30 | 440 | 4 | 16 | 15 | 1070 | 21 | ||

| 1000-112/132 | 590 | 300 | 570 | 4 | 26 | |||||

| 1000-160 | 790 | 420 | 700 | 5 | 33 | |||||

| 1000 | 1110 | |||||||||

| 1000-180 | 790 | 500 | 760 | 5 | 42 | |||||

| 1000-200 | 840 | 550 | 822 | 5 | 53 | |||||

| 1000-225 | 1000 | 590 | 941 | 6 | 53 | |||||

| 1120-112/132 | 590 | 300 | 570 | 4 | 20 | 15 | 1190 | 26 | ||

| 1120-160 | 790 | 420 | 700 | 5 | 33 | |||||

| 1120 | 1240 | |||||||||

| 1120-180 | 790 | 500 | 760 | 5 | 42 | |||||

| 1120-200 | 840 | 550 | 822 | 5 | 53 | |||||

| 1250-112/132 | 590 | 300 | 570 | 5 | 20 | 15 | 1320 | 26 | ||

| 1250-160 | 790 | 420 | 700 | 5 | 33 | |||||

| 1250-180 | 790 | 500 | 760 | 5 | 42 | |||||

| 1250 | 1380 | |||||||||

| 1250-200 | 840 | 550 | 822 | 6 | 53 | |||||

| 1250-225 | 1000 | 590 | 941 | 6 | 53 | |||||

| 1250-250 | 1100 | 590 | 1020 | 6 | 63 | |||||

| 1400-132 | 590 | 300 | 570 | 5 | 20 | 15 | 1470 | 26 | ||

| 1400-160 | 790 | 420 | 700 | 5 | 33 | |||||

| 1400-180 | 790 | 500 | 760 | 5 | 42 | |||||

| 1400-200 | 840 | 550 | 822 | 6 | 53 | |||||

| 1400 | 1540 | |||||||||

| 1400-225 | 1000 | 590 | 941 | 6 | 53 | |||||

| 1400-250 | 1100 | 650 | 1020 | 6 | 63 | |||||

| 1400-280 | 1200 | 800 | 1147 | 6 | 63 | |||||

| 1400-315 | 1400 | 300 | 570 | 6 | 63 |

NAME PLATE

Permanent metal nameplate should have clearly identifiable fan number, model number and product serial number (i.e., unique identification for each fan).

ACCEPTANCE INSPECTION

Before delivery, Falvent ensures that each and every fan undergoes a test run and final inspection.

SAFETY

Falvent supply all our tube axial fans with Ul & CE marking, which confirms that Falvent products conform to the American & European Machinery Directive and come with the corresponding documentation.

GUARANTEE

Falvent offers a guarantee of 24 months following installation for all fans.

A PARTNERSHIP FOR QUALITY

For most of our customers, purchasing a fan is not just a one-off event, but rather the beginning of a supply relationship that goes on for decades.