Car Parks Ventilation Overview

Underground parking plays a variety of roles in our daily lives, not only for saving ground space and clearing it of cars, but also allows to park a lot more vehicles. It can also allow a lot more storage space.

Underground car parks are generally unable to vent toxic exhaust fumes naturally, and the same is true of harmful smoke if a fire breaks out, due to there not being enough openings for the natural ventilation hence the mechanical extract systems are required.

Mechanical ventilation must provide 6 ACH (Air Changes per Hour) under normal conditions. In the event of fire this rises to 10 ACH.

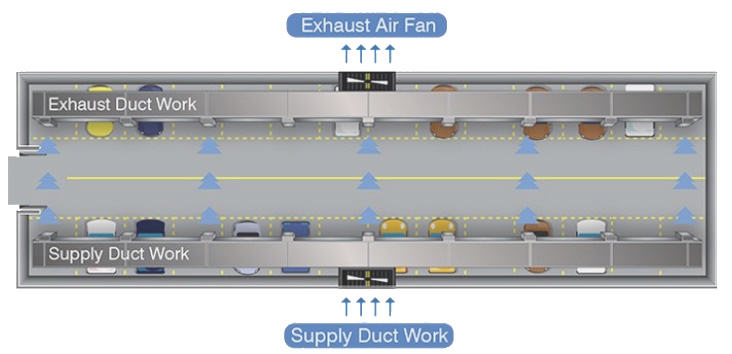

DUCTLESS CAR PARKS VENTILATION SYSTEM

Rectangular or circular ducts that are used to move air from the intake/exhaust to the desired location but that demands a larger space for ducting installation but this is difficult under constraint of a normally limited space in car park

Ductless designs use jet fans at specific locations over driveways to drive contaminants away without need for ducts as both to reduce levels of polluted air and to assist with the extraction of smoke in the event of a fire.

A jet fan is a long cylindrical fan that generates a high-velocity jet of compressed air ejecting from the trailing edge of the blade, resulting in the forward movement of air

JET FANS VS DUCTED SYSTEM

The advantages of using jet fans, instead of a conventional ducted system, are:

- Less ductwork to install making coordination of services easier and with no obstruction to other services.

- Lower height required, resulting in savings in the construction cost.

- Lower emergency power required thus, a smaller emergency generator set is required.

- Lower running energy cost, due to lower static heads required for the main fans.

- Lower operating cost.

- The ability to identify the origin of fires.

- Better air movement.

- Ease of operation (zone control is possible).

- Generation of lower noise levels.

- More pleasing aesthetics.

- Less cleaning of ducts.

- Better air distribution through greater air movement within car parks.

- can be operated to be fully reversible to move the smoke in one of several directions, depending on the location of the fire.

WHY WE ARE DIFFERENT

FALVENT is a Saudi manufacture offers a complete solution to meet underground ventilation needs during construction and after operation to achieve the air quality and provide standard ventilation.

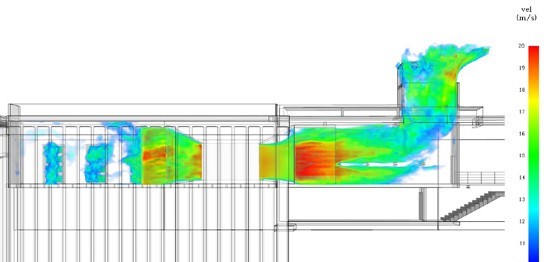

FALVENT work with a qualified consultants to delivery of projects on time, to an agreed cost and to the highest quality. In order to optimize our solutions, we also use advanced CFD analysis to get an effective performance.

FALVENT cooperates with the strategic cooperation with main advantage manufactories European and Chinese manufacturers specialized in tunnel ventilation to produce fans according to international manufacturing as well as in line with the Saudi market.

FALVENT starts working with its customers from the initial study of the tunnel, in order to provide an optimal solution for each project. Also, FALVENT has a technical assistance department with the following services:

- Installation and Erection.

- Testing and Commissioning

- Maintenance and Diagnostics

- Spare parts and Upgrade.

JET FANS AND MAIN AXIAL FLOW FANS

The jet fans and main flow axial fans can be used to clear the atmosphere inside the car parks and achieve the safe evacuation during the emergency case.

CARPARK JET FANS (CFC SERIES)

- Casing made of Carbon steel with epoxy paint protective coating.

- and provided with an adjustable bench that allows a wide range of motors to be installed.

- The silencers are placed on both sides of the fan casing and made with 70kg/m3 density rockwool and manufactured using perforated plate inside.

- and fitted with inlet and outlet cones designed for minimum pressure loss

- Protection guard for inlet and deflector in the outlet.

- Junction box on the casing for easy on-site wiring.

- Mounting support included.

- Impeller made of aluminum alloy

- Unidirectional or Reversible blade.

- TEFC Three phase motor, 380V/60Hz.

- Degree of protection IP 55.

- Calss of insulation F.

- Efficient IEC standard motor, efficiency class IE2 or IE3

- Specific bearings for operating between 20,000 h and 100,000 hours.

| Model | Thrust Tc in N |

Volume flow Qv in m³/h |

Rated motor power in kW |

Sound pressure level 3m in dB(A) |

Sound power level in dB(A) |

Item no |

|---|---|---|---|---|---|---|

| CFC 315 D2 | 4801 | 28 | 1,1 | 65 | 83 | 148040 |

| CFC 315 D2 F3 | 4801 | 28 | 1,1 | 65 | 83 | 148041 |

| CFC 315 D2 F4 | 4801 | 28 | 1,1 | 65 | 83 | 148042 |

| CFC 315 D42 | 4912/2401 | 29/7 | 1,1/0,25 | 64/47 | 82/64 | 148043 |

| CFC 315 D42 F3 | 4912/2401 | 29/7 | 1,1/0,25 | 64/47 | 82/64 | 148044 |

| CFC 315 D42 F4 | 4912/2401 | 29/7 | 1,1/0,25 | 64/47 | 82/64 | 148045 |

| CFC 355 D2 01 | 7197 | 49 | 1,5 | 70 | 88 | 148046 |

| CFC355 D2 F3 | 7197 | 49 | 1,5 | 70 | 88 | 148047 |

| CFC355 D2 F4 | 7197 | 49 | 1,5 | 70 | 88 | 148048 |

| CFC355 D42 | 7049/3641 | 50/12 | 1,5/0,37 | 68/50 | 85/68 | 148049 |

| CFC355 D42 F3 | 7049/3641 | 50/12 | 1,5/0,37 | 68/50 | 85/68 | 148050 |

| CFC355 D42 F4 | 7049/3641 | 50/12 | 1,5/0,37 | 68/50 | 85/68 | 148051 |

| CFC400 D2 | 10743 | 85 | 2,2 | 73 | 91 | 148052 |

| CFC400 D2 F3 | 10743 | 85 | 2,2 | 73 | 91 | 148053 |

| CFC400 D2 F4 | 10743 | 85 | 2,2 | 73 | 91 | 148054 |

| CFC400 D42 | 10020/5502 | 87/22 | 2,2/0,5 | 87/22 | 91/72 | 148055 |

| CFC400 D42 F3 | 10020/5502 | 87/22 | 2,2/0,5 | 87/22 | 91/72 | 148056 |

| CFC400 D42 F4 | 10020/5502 | 87/22 | 2,2/0,5 | 87/22 | 91/72 | 148057 |

For reversible jet fans will give approximately 5% lower thrust than those shown in the table

MAIN AXIAL FLOW FANS (AXF SERIES)

Falvent assemble and design the finest axial fans on the market with competitive prices and our team works hard to ensure that you receive the highest quality custom-designed axial fans, precisely as ordered and delivered on time to meet your project goals.

The range of axial fan sizes and capacities cover low to medium pressure systems for ventilation as well as for removal and transport of air within practically all environments. Falvent axial fans obtained the UL Certification which guarantees the compliance of the products with the safety requirements.

Falvent axial fans tested in accordance with UL-705 standard and certified in ZACT: Power Ventilators category and rigorous tests have been carried out via UL team like temperature test, water spray test, dielectric voltage test and starting current test. Thus, Falvent axial fans have product safety certification UL logo.

Falvent has met the requirements in ISO 9001, which defines an ISO 9001 Quality Management System (QMS) and obtained the ISO certification accordingly.

Falvent axial fans has CE mark logo where it declared with EEE regulations and meets the requirements of the relevant European product safety legislation.

| Model | Impeller Dia | Max Air Flow | Pout | Full Load Ampere | Voltage | Frequency | Phase | Speed | Noise Level | |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | m3/hr | m3/s | (Kw) | (A) | (V) | (Hz) | rpm | db | ||

| AXF 315 D2 0.55 | 315 | 3250 | 0.9 | 0.55 | 1.26 | 380 | 60 | 3 | 3450 | 346805 |

| AXF 315 D4 0.25 | 315 | 1550 | 0.43 | 0.25 | 0.739 | 380 | 60 | 3 | 1740 | 346806 |

| AXF 315 D4 0.37 | 315 | 1760 | 0.49 | 0.37 | 0.96 | 380 | 60 | 3 | 1740 | 346807 |

| AXF 355 D2 1.1 | 355 | 5880 | 1-Jan | 1.1 | 2.33 | 380 | 60 | 3 | 3450 | 346808 |

| AXF 355 D4 0.55 | 355 | 3100 | 0-Jan | 0.55 | 1.23 | 380 | 60 | 3 | 1740 | 346809 |

| AXF 400 D2 1.5 | 400 | 8600 | 2-Jan | 1.5 | 3.09 | 380 | 60 | 3 | 3450 | 346810 |

| AXF 400 D4 0.75 | 400 | 5150 | 1.43 | 0.75 | 1.71 | 380 | 60 | 3 | 1740 | 346811 |

| AXF 450 D2 2.2 | 450 | 12750 | 3.54 | 2.2 | 4.45 | 380 | 60 | 3 | 3450 | 346812 |

| AXF 450 D4 0.55 | 450 | 7100 | 1.97 | 0.55 | 1.23 | 380 | 60 | 3 | 1740 | 346813 |

| AXF 500 D2 4.0 | 500 | 19630 | 5.45 | 4 | 7.6 | 380 | 60 | 3 | 3450 | 346814 |

| AXF 500 D4 0.75 | 500 | 10400 | 2.89 | 0.75 | 1.68 | 380 | 60 | 3 | 1740 | 346815 |

| AXF 560 D2 4.0 | 560 | 23400 | 6.5 | 4 | 7.6 | 380 | 60 | 3 | 3450 | 346816 |

| AXF 560 D4 1.5 | 560 | 15300 | 4.25 | 1.5 | 3.15 | 380 | 60 | 3 | 1740 | 346817 |

| AXF 630 D4 2.2 | 630 | 22100 | 6.14 | 2.2 | 4.72 | 380 | 60 | 3 | 1740 | 346818 |

| AXF 630 D4 3.0 | 630 | 25400 | 7.06 | 3 | 6.98 | 380 | 60 | 3 | 1740 | 346819 |

| AXF 630 D4 4.0 | 630 | 29250 | 8.13 | 4 | 8.03 | 380 | 60 | 3 | 1740 | 346820 |

| AXF 710 D4 3.0 | 710 | 29400 | 8.17 | 3 | 6.98 | 380 | 60 | 3 | 1740 | 346821 |

| AXF 710 D4 4.0 | 710 | 32600 | 9.06 | 4 | 8.03 | 380 | 60 | 3 | 1740 | 346822 |

| AXF 710 D4 5.5 | 710 | 35100 | 9.75 | 5.5 | 10.4 | 380 | 60 | 3 | 1740 | 346823 |

| AXF 710 D4 7.5 | 710 | 39150 | 10.88 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346824 |

| AXF 800 D4 5.5 | 800 | 37450 | 10.4 | 5.5 | 10.4 | 380 | 60 | 3 | 1740 | 346825 |

| AXF 800 D4 7.5 | 800 | 42550 | 11.82 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346826 |

| AXF 900 D4 7.5 | 900 | 53000 | 14.72 | 7.5 | 14.2 | 380 | 60 | 3 | 1740 | 346827 |

| AXF 900 D6 4.0 | 900 | 41500 | 11.53 | 4 | 8.99 | 380 | 60 | 3 | 1150 | 346828 |

| AXF 1000 D4 15.0 | 1000 | 71850 | 19.96 | 15 | 28.7 | 380 | 60 | 3 | 1740 | 346829 |

| AXF 1000 D4 18.5 | 1000 | 77100 | 21.42 | 18.5 | 33.9 | 380 | 60 | 3 | 1740 | 346830 |

| AXF 1000 D6 5.5 | 1000 | 62270 | 17.3 | 5.5 | 12.5 | 380 | 60 | 3 | 1150 | 346831 |

| AXF 1120 D4 18.5 | 1120 | 79800 | 22.17 | 18.5 | 33.9 | 380 | 60 | 3 | 1740 | 346832 |

| AXF 1120 D6 7.5 | 1120 | 64900 | 18.03 | 7.5 | 15.9 | 380 | 60 | 3 | 1150 | 346833 |

| AXF 1120 D6 11.0 | 1120 | 72400 | 20.11 | 11 | 22 | 380 | 60 | 3 | 1740 | 346834 |

| AXF 1250 D4 37.0 | 1250 | 110650 | 30.74 | 37 | 66.1 | 380 | 60 | 3 | 1740 | 346835 |

| AXF 1250 D6 15.0 | 1250 | 92400 | 25.67 | 15 | 28.3 | 380 | 60 | 3 | 1150 | 346836 |

| AXF 1400 D6 30.0 | 1400 | 142500 | 39.58 | 30 | 58.8 | 380 | 60 | 3 | 1150 | 346837 |

VFD ROLE IN CARPARK VENTILATION

The variable frequency drive (VFD) controls the fan motor running achieve the effective control of the carparks ventilation fans as follows:

- Can be adjusted by the tunnel’s overall control system to meet changing air flow needs during the day.

- Has a very significant impact on energy consumption. Very small speed changes can yield large energy savings – a speed reduction of 10% results in a 27% energy saving.

- Reducing fan speeds can also reduce noise levels – reducing the speed by only 20% will reduce sound pressure by more than 50%.

- Helps in evacuation and fire suppression promptly changing fan speed and rotation direction according to a need.